How to choose casters

Using casters can reduce the work force and increase the work efficiency. The right caster should be chosen by themanner of application, condition and request (for example facility, laboursaving, durability). The factor must be con-sidered as follows:

THE LOAD CAPACITY

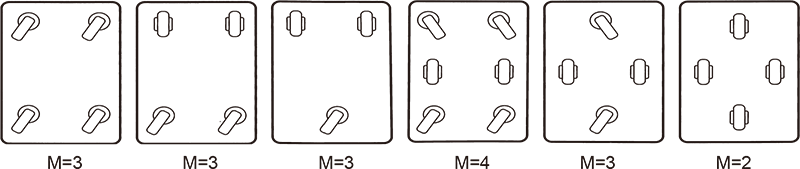

(1) Load: T= (E+Z)/M T= each caster load E= the weight of the vehicle Z= the weight of moving object M= efficient load casters quantity(the position and different heavy distribution must be considered)

(2) Efficient load caster quantity as follows:

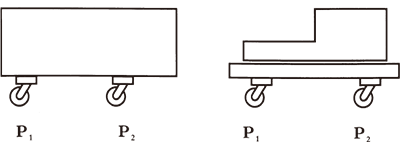

(3) The casters load at the position of maximum should be considered when choose load capacity.Concrete load positionand maximum position (P2) as follows

AGILITY

(1) The part of turn (frame turn, wheel rolling) should choose the mini, friction material, or the Accessories Which be made bya special thechnology, such as pin ball bearing or quenched in order that the casters will be used easy and durable.

(2) The more bigger the eccentricity is , the better the agility bocomes.

(3)The bigger the wheel diameter is, the more laboursaving it becomes, and can protect the floor surface perfectly. The big-ger wheels run much slowly,not easily getting heated and distorted, and more durable than the small t is better to choose thebigger diameter wheel when the fitting height is enough.

MOVING SPEED

The request of caster speed: at the normal temperature and on the smooth floor, the speed should be lower than 4kmh ofwalk and there is static interval during the work time.

APPLIED ENVIRONMENT

The floor material, barrier, leftover and the special environment, such as scrap iron, high or low temperature, great acidity andalkalescece,il liquor, chemistry solvent and anti-static-electicity, should be considered when choose the caster, Caster usedin special environment should be made of special materials.

Contact Us

Manager Dong:+86-18253256188

E-mail:china@shinhee.com

Address: Digital Equipment Industrial Park, Jimo, Qingdao

Ask For A Quick Quote